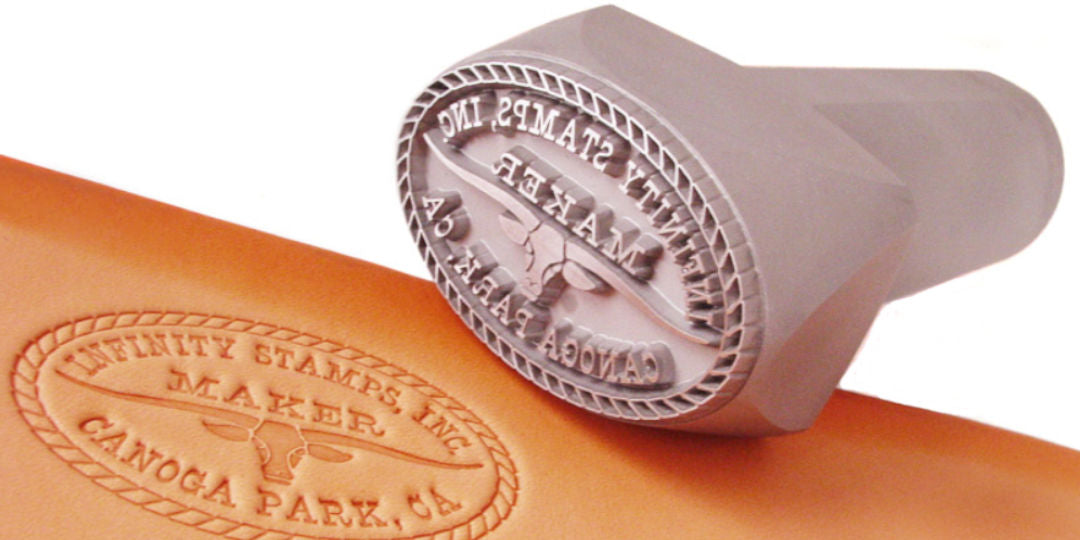

Custom Metal Stamps

Each custom metal stamp is made per customer specification. Customer provided artwork is reviewed and optimized to ensure clear marks for the intended size and material. We provide assistance and guidance as needed to deliver a product that exceeds the quality requirements for your project. When standard production option is selected, these stamps are shipped within 6 business days after proof approval.

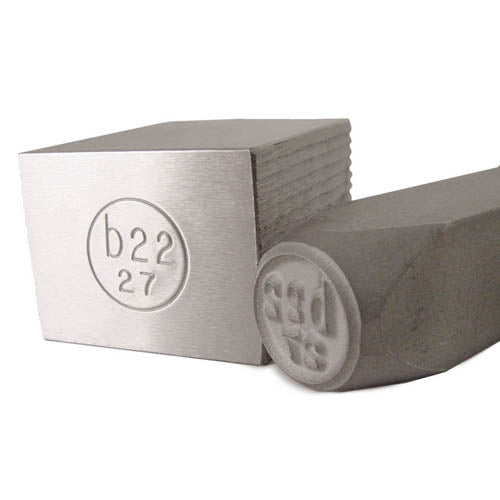

Whether marking aluminum, brass, gold, silver, or stainless steel, our manufacturing process ensures accurate reproduction of custom artwork. Designed to leave clear imprints, the stamp face is raised approximately 0.025" (0.635 mm) for metals or 0.045" (1.143 mm) for plastic to avoid or minimize ghosting -- a noticeable and unintended background mark. Accessories like the bench block, stamp holder, or ball peen hammer complement these metal stamps to improve the quality as well as consistency of each mark.

Our manufacturing process allows us to reproduce artwork with very fine detail and high quality. Heat tempered, tool grade, M2 steel are used to make durable, dependable, and detailed metal stamps. The top end of each stamp is beveled to prevent chipping when struck with a hammer. The corners of the stamp near the face are beveled to minimize or avoid unwanted background marks. A groove on one side of the metal stamp indicate the bottom of the artwork, ensuring proper and consistent orientation.